Today, I’m talking with Rivian CEO and founder RJ Scaringe. RJ was on the show last September when we , but the past 10 months have seen a whirlwind of change throughout the car industry — and at Rivian in particular. This year alone, the company has five new models in its lineup: the R2, R3, and R3X were all announced in March, and of its original R1T truck and R1S SUV just arrived with a complete update to the computing architecture inside the vehicles.

Listen to , a show hosted by ’s Nilay Patel about big ideas — and other problems. Subscribe ! In the biggest news of all, Rivian and Volkswagen announced a that will co-develop core parts of the hardware and software platform to be used in cars from both automakers. The deal will also obviously provide Rivian with a ton of cash — cash the company needs as it builds toward profitability and scale with the launch of the R2 in 2026.

A new partnership structure is absolute bait for , so RJ and I talked at length about how that partnership is structured and what Rivian is keeping in-house versus putting in the joint venture. Rivian has had , including a major relationship with Ford that came to an end. So I wanted to know what the VW deal would be different.

The answer might surprise you — RJ says this joint venture is set up to succeed because of the specific part of the technology platform in the cars it’s going to focus on. Of course, RJ and I also talked about the cars themselves — Rivian lent me an R1S to drive for a weekend before this chat, and it was a lot of fun. But it’s also a really expensive vehicle, and Rivian is still losing money on each one.

So I wanted to know how Rivian is planning to hit profitability on each car it sells and whether there’s more demand for EVs than some of the sales numbers we’re seeing might otherwise indicate. RJ really got into the weeds on this one — you can tell he’s spent a lot of time honing his theory of the case against Tesla and particularly against the Tesla Model Y. If you’re a listener, you’ve heard me talk to a lot of car CEOs on the show, but it’s rare to talk to a car company founder.

RJ was game to talk about basically anything — even extremely minor feature requests I pulled from Rivian forums. This is a fun one. Okay, Rivian CEO RJ Scaringe.

Here we go. Thanks, Nilay. Good to be with you here.

We’ve taken the approach of really approaching the software and the electronics in the vehicle from a clean sheet and developing those systems entirely in-house. So, even in our Gen 1 vehicle, the computers that were used across the vehicle, there were 17 different electronic control units (ECUs) that were built in-house. With the Gen 2 architecture, we consolidate that down to seven computers or seven ECUs.

That platform is more than just the computers and the network architecture, of course. It’s also the software that sits on top of them, and it’s something that allows thousands of dollars in cost savings. It makes it far easier to do over-the-air updates and software improvements because we’re not having to coordinate amongst many, many different suppliers.

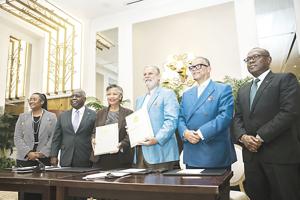

What we’ve created is of a lot of value, and we’d been in a discussion with the Volkswagen Group for a long time about how we might be able to work together. Ultimately, what was announced was a joint venture whereby, through a combination of investment and then some licensing fees, to us, it’s a $5 billion deal — $5 billion comes into Rivian, and then in exchange, we create with them a joint venture that leverages our technology. We’ll see it across a host of different products: Porsche, Audi, Lamborghini, Bentley — of course the full portfolio of Volkswagen-branded products.

We love that because it aligns so beautifully with our mission: the ability to help accelerate putting highly compelling electric vehicles into the market, which will ultimately drive more demand. Thanks for clarifying that. There’s vehicle platform.

There’s battery platform, driving platform. This is just our electronics platform. You could also refer to this as our network architecture.

So, in our case, it’s a handful of computers that are zonally located within the vehicle, meaning they’re controlling functions within a specific geography or zone versus having a purely functional purpose around a specific feature. Most vehicles in the world today — I’d say with the exception of us and Tesla — have domain- or feature-based architectures, whereby a normal car might have 70 or 80 or sometimes a hundred ECUs. There’s an ECU that controls the seat.

There’s an ECU that controls the window mechanism. There’s an ECU that controls the HVAC system. There’s a powertrain control ECU.

So, you end up with this massive proliferation of complexity of lots of little computers or microcontrollers that are built by a range of suppliers and tier ones, which makes it really difficult to not only control software within the vehicle to make updates to the software. To illustrate the point, in a traditional vehicle, if I wanted to change the sequence of events that occur when I walk up to the vehicle with my phone in my pocket or my key in my pocket..

. to do that in a traditional vehicle, you’d have an ECU that’s controlling the vehicle access system. You’d have an ECU that controls the locking system in the car, an ECU that controls the seats so the seats get into the right position, an ECU that controls the HVAC system, and an ECU that controls the overall infotainment platform that has to come up and come to life.

Each of those are different companies. For something as simple as “I want the vehicle to make a noise when I walk up and open and have this ingress or entry experience,” you’d be coordinating between 10 to 15 different ECU suppliers. That process — to make an update to that feature — could take months.

Within Rivian, it takes minutes. I mean, it’s all our stack; it’s all our software. In that scenario, we would be using one ECU to do everything I just described.

In this case, it’s a much larger computer, but one computer. It’s a massive simplification for how we think about software development and also drives a lot of cost out of the vehicle because instead of 70 to 80 little boxes — little computer boxes with wiring and connectors and everything else — we have, in our case, seven. [Laughs] Yeah.

The CEO of Volkswagen Group, Oliver Blume, and I have spent some time on this. When we announced the deal, we each spoke to it, and what gets me so excited about this is the portfolio of really strong brands that exist within Volkswagen Group. You think about Porsche or Audi and the necessity for those brands to have a step change in terms of the technology set to really make sure they’re at the leading edge.

It’s just such a nice complementary set of capabilities, our technology with their products. What we’re providing is that architecture. We’ll provide the topology of the ECUs, along with the base operating system.

That’s both for the infotainment platform, but also for the real-time operating system. There’s a few different operating systems we’ve built, and then everything around over-the-air updates and connectivity. But what we won’t be providing is our user interface.

In all the different products this platform will go into, the user interface is actually an abstraction at the top of the stack. A vehicle may have three screens, it may have two screens, it may have 10 screens. That’s relatively simple to change what the UI looks like, but everything underneath will be really heavily commonized using our architecture.

That’s ultimately going to be a decision for each of the brands: what they want their UI to feel like. The beauty of the platform we have is in terms of compute and graphics capability. We talked about the speed of communications across the different computers.

It provides a very high ceiling in terms of what one might dream up. One of the other benefits of this relationship is if you think of it almost like there’s going to be a library of different features and content and frameworks we develop around the features and content that can be applied across different applications. So we’ve developed a very, I think, wonderful integration with Unreal, which allows us to do these unique renders and a very unique style that we’ve designed that’s intentionally not photorealistic, but rather more artistic and interpretive.

You could use Unreal Engine to render any style, and it’s such an enabler for making the product feel really fresh, in our view. That’s ultimately going to be the decision of the brands, but it certainly could be in there. Our UI design team stays within Rivian.

Of course, outside of this — things like drive units, battery systems, vehicle platforms, our autonomy system, our perception stack, steering systems, braking systems — all those systems stay fully within Rivian. What goes into the joint venture is this family of ECUs. The team that continues to develop these ECUs is essentially the computer design team.

Then, there’s the software team that builds from the base layer from an operating system point of view, up through the various applications, and then some of the execution team. But the design functions..

. like we expect to be working with the design teams at different brands, not for those design teams to move within Rivian. It’s the same case with us.

So, what we see in terms of the graphics, of course that has to be executed from a technical point of view, but the overall UI design and UI framework within Rivian, that reports up through our design team, not through our software team. Generally, that’s the case at most manufacturers, that they have their own UI design team. That’s a good question.

Yeah, so it’s a 50/50 joint venture. The way we’re structuring it is there’s a CTO-CEO that Rivian appoints. We have not announced who that is.

And then there is a– [ ] Yeah, this is the time. You can probably guess. That role will also have a role within Rivian, so it’ll be, in some ways, a dual role.

Then there’s a more operational leader, a co-CEO, that Volkswagen appoints. If there’s any issues that aren’t resolved in terms of, let’s say, resource allocation, it escalates immediately to myself and the Volkswagen Group CEO [Oliver Blume]. He and I have an outstanding relationship.

We are both huge car enthusiasts, and — I think I’ve mentioned this to you — I’m a lifelong Porsche enthusiast. I grew up restoring classic Porsches, so we were kindred spirits from the very beginning of these discussions. That’s a great question.

It’s an area we spent a lot of time on in terms of structuring the way that governance was set up, making sure the things that work so well within Rivian continue to work that way, and working closely with the Volkswagen Group side of things. They would not be spending $5 billion on Rivian if they didn’t want to keep things working the way they were. A core objective of how we’ve structured the joint venture is that we don’t lose the velocity and the speed and the decisiveness and lack of bureaucracy that exists within our software function today.

So there’s both the hardware side and the software side. On the hardware front, because of the breadth of vehicles the platform will be applied to, there will be differences between the ECUs — the computers that go into every car. I shouldn’t say it’s not necessarily the case, but it’s likely going to be the case in a number of ways.

Imagine a vehicle that has eight screens, eight multi-touch screens, versus a vehicle that has one multi-touch screen. Across the portfolio products will ultimately support, that’s very realistic. The input / output, so to speak, on what we call our experience management module, which is the computer that runs the infotainment platform, will need to be different.

But the team that runs that platform, it’s a very simple change for us because it’s all in-house. It’s not like we have to go back to some supplier and say, “Hey, we need to have output connectors to support this many screens.” We can spin up new boards really easily.

I’m not concerned about that. That’s straightforward and very easy to understand. The bigger question, though, is making sure that we’re not bringing up a wide range of different compute platforms.

What silicon we select, and what silicon we really build around for certain aspects of this — whether that’s the core compute platform, whether that’s graphics — we want to keep that consistent across the family. Beyond just simplification of how we manage running over-the-air updates across so many different instances, it also gets us a lot of supply chain leverage in a way that we, Rivian, haven’t had in the past. You can imagine when we talked to silicon providers in the past, they’re looking at Rivian’s volume and providing a certain price.

We now look at it across not just our volume, but the breadth and strength of Volkswagen Group’s volume, and we expect considerable cost efficiencies to result because of that. In fact, you can imagine the day of the announcement, I had a handful of phone calls from CEOs of big semiconductor suppliers, and they’re like, “Hey, we can work harder on pricing.” So, that was awesome.

I mean, it goes from Rivian being a small customer today to then, “Oh wow, Rivian is going to drive a huge amount of volume through our partnership with Volkswagen.” Yeah, and these supply chains tend to be sticky. Once we select a platform, it’s not to say that that platform’s going to stay the same for the next 10 years.

Of course, that platform’s going to continue to improve, but the frameworks around how we develop on top of that platform stay consistent. We’ve done this already with the Gen 1 to Gen 2 transition. Even within Gen 1 and within Gen 2, there’s improvement that we have enhanced chips that are going into the vehicle, but it’s within the same supplier.

The decisions we make over the next year and a half are by no means forever one-way-door decisions, but there are switching costs associated with it. That only becomes stronger as the scale of the portfolio becomes larger. It’s in the interest of both sides to think about the long term.

In our case, we want to say, “Is this a supplier that we want to work with, ideally for the next decade or beyond, ideally beyond?” And for the supplier, “Does this customer represent significant annual year-over-year growth?” In our case, we now can say very, very affirmatively that, “Hey, look, we have R2. We have R3 coming. That represents growth.

” But think of the entirety of Porsche, Audi, Volkswagen, Lamborghini, Bentley, SEAT — like all the brands within Volkswagen Group that will be electrifying. As those vehicles electrify, they will also be using this platform. I mean, we have the most leverage we’ve ever had in the history of the company.

I don’t think it needs us to. Well, it’s interesting you bring up all the examples of other partnerships, and we’ve seen this now we’ve looked at the idea of sharing our vehicle platform through a variety of lenses. We looked at vehicle platform sharing with Ford, vehicle platform sharing with Mercedes, both very publicly.

As you alluded to, we’ve looked at big platform opportunities with other vehicle manufacturers as well. What is, in every case, always the challenge is getting the network architectures of Rivian’s platform and those other manufacturers that we’ve talked to to work together. It’s a challenge in every possible way.

It’s a challenge to get the top hat from a traditional company that’s using lots and lots of supplier source ECUs to work with our platform — battery, drivetrain, chassis that has very few ECUs. It’s a challenge to get those two very different architectures to run down the same manufacturing line. And by far, putting aside the strategic reasons those deals didn’t happen, the biggest technical boundary was always network architecture.

As we’ve approached this with Volkswagen, interestingly what we’re partnering on is precisely the thing that has always been the challenge. So, while this deal is purely around aligning our network architectures, it certainly makes things like platform sharing a lot easier and leveraging manufacturing capacity a lot easier. But we didn’t start there.

We started instead to say, “Let’s align network architectures,” and this doesn’t have packaging constraints. We have to fit a handful of small computers or small boxes into the car. They can go in many places, but it doesn’t have any link to the way the vehicle drives, the way the vehicle looks.

It really just enables this software platform to be much more compelling as we discussed. So, taking away all those mechanical design studio packaging constraints that we had before, and then solving the biggest challenge, which was network architecture by this being that as a project, it’s just a very different type of relationship. If I could go back in time, I think we would’ve probably realized that bigger than sharing batteries or bigger than sharing motors or bigger than sharing the combination of those two was the opportunity to leverage our electronic stack.

The way the deal is structured is it’s a $5 billion deal, and $3 billion of it is structured as an investment. We intentionally structured that to be staged over time, given the desire to minimize dilution and the desire to essentially have that future second and third billion come in at a higher share price after we’ve achieved some success. Even the first billion came in, and only half of that converts at the share price at the time of the announcement.

The other half converts when we finalize the definitive agreement for the joint venture, which of course is very advanced, but that allows for us to minimize dilution, even in that first billion. That’s the first $3 billion, it’s equity. The other $2 billion is in conjunction with the joint venture.

One of those is the licensing fee back to Rivian, and the other is debt provided from Volkswagen to Rivian. It’s structured in a way that gets paid off through the joint venture over time. But the goal is it inserts $5 billion onto our balance sheet, and so it really provides the funding roadmap to get to positive free cash flow and takes the balance sheet risk off the table.

That $5 billion doesn’t include any of the revenue associated with the joint venture or any of the operating expense improvements associated with the joint venture. We will talk about those numbers at a later date, but those are not insignificant, as you can imagine. In what way? With regards to the joint venture? Well, within our software function, a significant portion of the software team — I should say the vast majority of the software team — will be part of this joint venture.

The joint venture will look, feel, behave like Rivian. It’ll be a Rivian entity, but it’ll have ownership that’s not just Rivian but also Volkswagen. The objective is to make it look and feel as much like Rivian as possible, and that’s from a recruiting point of view, that’s from an equity compensation point of view.

All of the above. We’ll be leveraging our existing facility’s footprint. We’ll be growing the team, not surprisingly, to support the much greater scope of work that we’re now going to have from an applications execution point of view.

Then, from an electronics point of view, the subset of our electrical engineering team that’s responsible for the design of these computers will move in. But with the exception of our self-driving platform, both the perception — so, the cameras we design in-house, the radar systems, and the entirety of the compute platform, the design of the computer system, the chip selection — all of that will stay separate from this joint venture. That stays completely within Rivian.

It stays the same. I lead all products; all the product functions report to me. There’s a propulsion lead that has drive units and battery systems reporting to him.

There is an electrical lead, which has all electrical hardware — inclusive of computers, cameras, silicon selection — reporting, in this case, to her. We have a chassis body interior lead. You can think of it as the traditional vehicle leader that has all the bits you see — that reports into me.

We have a safety and attributes leader, and attributes are all the characteristics of the vehicle that we test and design requirements around, that reports to me. We have a program leader that’s responsible for running the programs both on the consumer side: R1, R2, R3. On the commercial side, our EDV reports into a single program leader.

We have a head of design who reports to me. So think of it almost like there’s a vertical function around a capability set. So, body interior chassis, that’s a team.

But then there’s programs within that. Within the body chassis interior vehicle team, there’s an R1 team, there’s an R2 team, an R3 team. And individuals move between those.

So, one can imagine the vast majority of those teams are now on R2. There’s very few people that are supporting R1 because we’ve launched the update and it’s stable. The significant portion of the company is on R2 or R3.

The same is true for propulsion. We just launched all-new drive units — new quad, new tri, new battery packs in R1. Those teams are all now really heavily dedicated to R2.

Even before the launch of Peregrine, you can imagine a lot of the teams are already on R2. So that structure, to be capable of running and operating multiple programs at the same time, has evolved. We’ve worked on it quite a bit, but I’d say it’s one of the best functioning parts of the business today.

I don’t know. One of the things that I’ve realized and worked toward was to have as few degrees of separation between me and the teams that are doing engineering. Often within large car companies, in part because of their scale and I think just in part because of the history, there’s quite a few layers between the actual technical leaders that are making technical decisions and the CEO.

Whereas, within Rivian, the technical leaders report directly to me, and it means I have a large number of direct reports. The whole product team reports to me. That’s with my chief product officer hat on, and then I have the CEO side of my role.

I have a CFO that reports to me, a general counsel reports to me. The way I run the team is I have a product leadership team meeting. My regular staff meetings are on product leadership, and we have quarterly off-sites and all the things you’d expect for someone who’s running a product and technology organization to do.

Then, I have a similar set of meetings that happen from an executive leadership point of view. In the executive leadership team, I’m both the CEO and I also represent product. That’s worked really well, but it’s also something that we’ve iterated on quite a bit as a team.

For me, it took a while to make sure we had the right leadership team that would give me the bandwidth to be as focused on product as I am. To see if it still works? One of the things I’ve learned over time is that the right organizational structure in two or three years is likely different from the organizational structure that’s most effective today. When I’ve preemptively tried to pull what I think will be the future state organization structure into today, it generally is the wrong decision.

So, if I said, “Let’s design this to look like a company that has 10 different products,” theoretically, you can understand why we do that. We’ll say, “Oh, we’re getting ready for when we eventually have 10 different products.” But that’s so in the future that, right now, we don’t.

We have an R1, and we have a new platform, which we call a mid-size platform, but it’s R2 and R3, which is a sibling set of products. Those products need to be home runs, over the fence, just absolutely insanely good. The whole future of the business depends on it.

There’s not a lot of decisions that we’re taking lightly. We’re looking at every inch of the vehicle and, in the case of R2 and R3, really, really focusing on costs. So that, out of the gate, they have a much better cost structure than what we launched with on R1 so that we can get to scaled profitability and healthy, positive free cash flow.

In our business, I say this all the time, but the thing about a car is the number of decisions is so significant. I mean, we’ve tried to estimate it — I would argue there’s many tens of millions of decisions necessary to be made in the development of a car. And so different than if you were designing, let’s say, a whiteboard or a water bottle where conceivably one or two people could make every single product decision on the entire thing.

By necessity, unless you’re going to take 20,000 years to develop the product and live forever, you need to have a lot of people working in parallel making truly thousands of decisions every day. Those decisions may be really big, like what’s the size of the battery pack, to really small, like what’s the radius on the corner of a part to minimize stress concentration. What we’ve done is try to ensure that, to the extent possible, the many millions of decisions we’ll make over the course of developing a product feel as if one single brain made all those decisions.

We talk a lot about the philosophy of how we make decisions. So, what’s the purpose of the product? What are the tradeoffs we’re willing to make around cost versus performance versus perceived quality? We have lots and lots of iterations around reviews, and we essentially work really hard to train the organization so that the front of the vehicle feels like it was designed by the same team as the back of the vehicle. The way we approach cost optimization in the interior feels consistent with how we’ve approached it in, let’s say, the chassis system.

We don’t always get it right. There are mistakes that get made; we have to fix them. There are mistakes that get made that we have to address, but we do really consciously understand that we do need to make a lot of decisions.

So, for us to be functional, we have to have highly distributed decision-making. We built some frameworks around this so we understand in the decision who’s the decision-maker. We say, “Who’s the D?” Who do we need to inform about the decision? Who are the people that have to be a participant in providing input into the decision? Let’s say a part that comes together, let’s say, a welded assembly or cast past.

Probably one person can make that. There’s probably not a lot of people involved. But on something like what’s the door opening look like on the car? There’s 50 people that’ll be involved in that.

There’s a seal team, there’s a window team, there’s a door closures team, there’s a scuff and paint quality team. There’s a lot of people that play into that, and some of it takes practice. When we first started, we didn’t have as much experience making these kinds of distributed decisions, and now it’s like I really feel on R2 where the teams are flowing, the things that we can’t reach a decision on get escalated.

Ultimately, if the escalation point can’t make the decision, it escalates again, and it gets to me. Then, my role is to help navigate to a decision. But I’d say I end up, as a percentage of total decisions, making a very, very small percentage of the decisions.

I participate in the big decisions, but every day, as we’re in this conversation, many decisions are getting made as we speak. I think a lot about Amazon’s strengths because Amazon invested in us in 2019, about two years before we launched our first product. That influence has been really helpful.

I think one-way doors are a key part of their decision framework, which, if a decision is a one-way door and it has big implications, spend time on it. If a decision is reversible and doesn’t have huge implications, make it quickly. That’s certainly true in a vehicle.

The nature of our product, there’s 30,000-plus discrete parts, 2,500 sourced components. There’s just such a large volume that it’s inevitable that mistakes or things will get done without something having to be revisited. So I think the one-way door concept is a big one that we connect with and associate with.

The other thing that we try really hard to achieve — and we don’t always achieve this, and I’d say that I don’t think there’s any company in the world that always achieves this — is absolute clarity around who is responsible for the decision. Because it’s key for accountability. It’s a critical element for how we truly enable scaled, distributed decision-making.

So we do spend time on that, and if something’s unclear, like you’ll be in a meeting and you find yourself in this infinite loop of debate, you’re like, “Wait a second.” You say, “Who’s the D? Who owns this decision?” Somebody will raise their hand. “Okay, what do you think? And why do we not have a better framework?” It’s just a very efficient way to help navigate driving the efficacy of the teams.

I was the D on that one. It saves us $2.25 billion in capital through the launch of R2.

That’s a big important one for us, particularly as we want to make sure we have a really robust balance sheet going into the launch of R2. Certainly, we made that decision before we had secured the $5 billion from the Volkswagen deal, but it’s still absolutely the right deal to make sure that $5 billion now takes us through positive free cash flow. So, the first is capital efficiency.

The second is a recognition that Normal is producing the R1 and the R2 platform and our commercial vehicle. Across each of those vehicles, if you sum it up, we have 65,000 units of commercial vehicle capacity, 85,000 units of R1 capacity, and we will have 155,000 units of R2 / R3 capacity. The beauty of that is those numbers sum up to more than the total capacity of the plant.

Total capacity of the plant is 215,000 units a year, and it’s limited by the paint shop currently. It gives us a lot of fungibility between R1 versus R2. In a world in which there’s a lot of unknowns — the interest rate environment, because of that overall willingness or capability to spend on a vehicle in terms of monthly payment or total cost — it allows us, in the event interest rates are still high and customers are more price sensitive, to flex up on R2 and flex down on R1.

We really like that there’s no risk of cannibalization between R1, R2, and R3 because we’re somewhat indifferent as to which Rivian someone buys, as long as it’s a Rivian. So it’s a nice way to have the first plant launch where it takes some of that risk out, and that’s a question we get asked all the time: are we worried about cannibalization? But the third reason was it allows us to minimize the risk of launch and speed the launch up because we’re taking a team that we’ve — over time, painfully in many ways — brought to a place where it’s now working well. When we launched, we didn’t have experience in training.

We didn’t have experience in running a plant. We now have a high-functioning team, so we said, “Boy, it’d be great to take this high-functioning team and launch the next platform.” And so, rather than launching first in Georgia where we have a new plant, new products, new teams, some new technology all at once, we’re now going to have new products with an existing plant and an existing team.

So, it’s a way to reduce the amount of time to market and remove the risk. Now, saying that, Georgia is still a really important part of our overall strategy and, in terms of R2, our largest R2 plant. It’s a 400,000-unit-a-year plant; that’s what’s been designed.

We say we’re going to get to positive gross margin. No, that’s it. The thing to keep in mind is we are investing very heavily into technology platforms and vehicle platforms that are designed for scale.

If we look at what we produce today, this year, our guidance for the year is 57,000 units of production and roughly 57,000 units of deliveries. But we’ve got completely in-house electronics, completely in-house software stack, in-house perception stack that we just launched on the Gen 2, complete in-house autonomy. Each of those are huge development efforts and we’re making those because we’re bullish on the long term for the business, and we believe the structural cost advantages and structural performance advantages that result in the end are worth it.

But that base metabolism of the business that results from being so heavily vertical in those areas means we need a certain level of scale to cover that. That’s always been the case that we , and that’s why R2 and R3 and that platform is so important for scale. What we didn’t anticipate, if I were to wind the clock back to 2019 or 2020, is when we were sourcing R1, we had to go out to suppliers in 2018 and 2019 when the auto industry was at peak volume, so things were humming.

We had to go convince suppliers to spend time, resources, and bandwidth on supplying us parts in 2018 and 2019. A brand that was very unproven, for a company that didn’t have a working plant for a product that wasn’t yet complete, and in an environment where it wasn’t clear how rapid the demand for electrification would grow. We had very little leverage, so we had to sign up for massive risk premiums for sourcing the bill of materials that went into the launch configuration of R1.

Our assumption all along was that, as soon as we launch, we’ll see the success, those companies will want to continue working with us on R2, and we’ll have leverage to then negotiate those risk premiums down. We’ve made some progress that you can see in our quarter-over-quarter improvements. What we didn’t anticipate was the supply chain crisis.

The . All these suppliers that we thought we’d be able to say, “Hey, look, we’re doing great. It’s the bestselling premium EV in the United States.

The R1S is the bestselling premium vehicle EV or non-EV in California, and we’re about to launch R2 work with us to come down on cost.” Those suppliers said, “Actually, we don’t have enough supply. Can you pay us more money?” It was just like a perfect storm, and we finally have gotten through that where we’ve resourced a very significant portion of our bill of materials for any of those suppliers that worked with us.

That was great. They lowered the price, they treated us as a long-term partner. For the suppliers that didn’t, that weren’t willing to remove the almost extortion-level premiums, we had to move on.

We had to break those supply agreements. We had to go bring on new suppliers, suppliers that wanted to be part of our long-term story. That’s a lot of effort to replace the bill of materials in a car.

No, that was more of a technology move. That’s more on things like windshields or seats or stamp metal parts. It was the rest of the vehicle that had to be resourced.

You said you were at the R1 event; you saw it. I mean the car looks very similar, but most of it is new, everything under the surface is new. That is what’s giving us this step change in cost structure, which we’ll start to see near the end of the year.

Back to your capture of my statement, which is that we’ll be positive gross margin by Q4 this year. Yeah, the dual setup, imagine four of those. The quad motor is nuts.

So, what you drove, it sounds like you were in a dual-performance Max Pack — our biggest battery pack with our two-motor system, a performance variant of that. So, as you said, probably $90,000. I don’t know exactly what you had.

But the base price on the vehicle’s around $75,000 to $76,000 for the base R1S, which is a smaller battery pack, very similar drivetrain to what you had, so similar acceleration. One of the things we focused on when we developed the product and the portfolio was to give people choices along the price spectrum. So, if you’re highly price-sensitive, you can get something that’s really nice for $75,000 or $76,000.

If you want a lot more range or more performance, you can spend up from there. With the new tri-motor and then our updated quad, it allowed us to move the pricing levels even higher for the highest spec because the performance is now..

. it’s just so staggering. Well, we think the R1 product has always been thought of as our flagship vehicle, so it’s going to be our highest-price vehicle.

We think there’s a subtle difference, but it’s important. We think of them as very premium vehicles, but not luxury because they’re vehicles that are designed to be used. You can get them dirty.

You can drive them off-road. Yeah, they’re designed to be heavily used. That’s good.

I like that. That’s hilarious. So, the R2 is a much lower-cost architecture.

We had an investor day where we talked about some of this, but it benefits from some of the supply chain leverage that I talked about before, where we’re sourcing this from a very different vantage point. The R1’s success has been really helpful in sourcing R2 because many of these suppliers, which I remember meeting with in 2018 and 2019, decided to put pricing that had a lot of premiums. What they’ve seen is basically what we’ve said we were going to do, we’ve done.

The volumes we anticipated, we’re now hitting. They also see that the R1 has been a huge market success in terms of electric vehicles over $70,000. It’s, by a significant degree, the bestselling vehicle.

So it outsells Model S, it outsells Model X. In that premium segment, it does really well. The hope is if we can take the success we’ve had at price points, as you said, north of $70,000 and translate that to price points north of $40,000 — if we have any semblance of the market share that we’ve been able to capture at the high end at this more middle-price band, call it the average, near the average, transaction price of a vehicle in the United States — we hope that will translate to significant volume, certainly well beyond what we can produce in Normal, and allow us to turn on our Georgia facility to supplement the demand that exists there.

Yeah. As we said, this Q4, we’ll be positive gross margin. On a unit basis, it’ll make money by the end of this year.

The scale of our operating expenses, the scale of our R&D is very large, so the denominator of R1 revenue just isn’t big enough. We need more volume to cover all of our operating expenses. But the question of does making one more car lead to us having more or less money, the answer to that will be yes, it will lead to us having more money, which wasn’t the case when we started.

Yeah, so that’s a big difference. We haven’t said any of this, haven’t given any of the numbers yet, but sourcing R2 has been about as different as one could have ever imagined from R1. I’ll use an anecdotal example just to illustrate the point.

On R1, when we would be sourcing lots of the components, I would go to Detroit to meet with suppliers and maybe I would get a vice president to meet me in some conference room after waiting in a lobby for 30 minutes for a meeting that the supplier’s late to. More often than not, it’d be like a senior manager of sales or maybe a director of sales. We were very low in terms of how those suppliers prioritized us.

If I contrast that with the same systems at the same suppliers on R2, the CEOs of those suppliers are flying to Normal, Illinois, to meet with me. It is such a different sourcing environment. The pricing that we’re seeing for similar components is much, much lower.

Now, on top of that, we’ve architected the vehicle to be simpler. R1 is a pretty remarkable thing. It’s active damping.

It’s got electrohydraulic roll control. It’s got massive adjustment in the ride height with air suspension. Whereas, with the R2, it’s a passive spring, semi-active damper, pretty straightforward.

It has a passive anti-roll bar in the chassis system. Body architecture isn’t designed for the extreme off-roading of what we see in R1. It’s still a capable vehicle off-trail, but it’s nothing like what we did with R1.

It’s funny you say latent demand. I actually use that exact phrase all the time. There’s a massive amount of bias that’s gone into describing what’s happening in terms of EV growth and the causality of its slowdown in growth.

Notice I said slowdown in growth. It’s still growing, just not growing as fast. But the causality of that is something that we can debate, and I think more often than not, people are signing the causality to say there’s not a lot of demand for EVs.

Often, the folks that are saying that are saying that because they’ve developed and launched EVs that haven’t done that well. What I would say is the primary reason for the slowdown is there is an extreme, truly extreme, lack of choice. If you want to spend less than $50,000 for an EV, I’d say there’s a very, very small number of great products.

Tesla Model 3 and Model Y are highly compelling, great products, but they don’t have a lot of competition. The products that are trying to compete with them more often than not, without being specific, have unfortunately replicated the package, the shape, the overall proportion of the vehicle, such that they’re not a Tesla-branded vehicle, but the side view centerline of the vehicle is almost identical to a Model Y. The seating package is within millimeters of a Model Y, the performance is slightly worse than a Model Y.

Ironically, because of the Model Y’s success, you have a lot of incumbents that have built products that look and feel and are shaped a lot like a Model Y. That’s very different from the internal combustion space where you have hundreds of choices, lots of brands, lots of variety of form factors. What we’ve witnessed over the last few years is because of lack of choice, we’ve had a lot of customers that have gone to one single brand and have had to have a lot of elasticity of their form factor desires.

So maybe they wanted a true SUV and got a very car-like crossover with the Model Y. Maybe they wanted something that was a little bit bigger, but they got something that was more like the Model Y. Maybe they didn’t love the Tesla look, but it’s the best product, so they took the Model Y.

I think you have a market that’s fairly saturated with Teslas, and I think the customers that are waiting on the sidelines saying, “I bought a Toyota RAV4, I bought a Highlander, and I want that kind of SUV-like profile, but I want an EV, and there’s nothing out there for me,” they’re probably still waiting. We see that evidenced through the really positive reaction to the R2. The R2 very intentionally, much like we did with R1, is not trying at all to be a Tesla Model Y.

It’s going to compete from a price point of view, with very similar pricing. It’s a very similar size. It’s slightly shorter than a Model Y, but it’s not trying to replicate a Model Y.

I think that’s not to say Model Y isn’t a great car. I think it’s an awesome car. I’ve owned one before.

It’s just to say that I think the world needs more variety. Our view is that there is — and to use your word, which I love the word — there is massive latent demand that’s sitting on the sidelines waiting for the vehicle that has the form factor, the packaging, the branding, the look, that will cause them to switch from a combustion-powered vehicle. Yeah, look, we try hard not to get drawn into politics or even having a point of view around Elon’s political points of view or political preferences.

I think at the end of the day, we think about it in terms of creating great products. To the extent that the products are really compelling — and we see this with R1, we also have seen this with the orders that are coming for R2 — whether you’re on the right side or the left side of the aisle, if it’s a great product that’s exciting, that fits your needs, we hope to draw from both sides. Ultimately, if we really are committed to electrifying the entirety of our transportation system, we need to get far right, far left, middle, everything in between.

The strength of the product needs to do that. I think Tesla has shown that with their products. Their reduced market share, I think causality is always a hard thing in something like this.

It can be somewhat subjective to ascribe exactly what’s driving their reduction in market share. But I do think we’re talking about two incredible products that have been on the market for a while and for which there are a lot of them on the road. I think there’s a desire for variety.

You and I talked about this before. This is a question that certainly you see a lot of buzz around on the internet. Some of our customers make some noise about this.

We’ve taken the view of the digital experience in the vehicle wants to feel consistent and holistically harmonious across every touchpoint. In order to do that, the idea of having customers jump in or out of an application for which we don’t control and for which doesn’t have deep capabilities to leverage other parts of the vehicle experience..

. for example, if you’re in CarPlay and want to open the front trunk, you have to leave the application and go to another interface. It’s not consistent with how we think about really creating a pure product experience.

In order to deliver the features that are desired within CarPlay, we are starting to do that, but on an à la carte basis. We’re just . We have a great relationship with the Apple team.

It’s in partnership with Dolby Atmos. You probably heard it if you’re at the demo, it’s a big step-up improvement in the audio performance of the vehicle. It’s awesome to have Apple Music in the car.

We’re just launching YouTube in the car. But we want to be the curator of getting as many different platforms and applications into the vehicle. Whether that be YouTube or Spotify or Apple Music or Prime Video.

We do really believe in this, and I think the biggest complaint today around the lack of CarPlay is the improvements we need to make in mapping, which are coming. But again, even in mapping, we want to be able to separately select routing, separately select base maps, separately, select points of interest. Overlay that with charging routing, which is really important and is highly specific to the vehicle itself, and highly specific to the networks and the ratings on those networks, which we .

We just believe that it’s such an important piece of real estate, the digital ecosystem, that it was something we wanted to retain. We recognize that it’ll take us time to fully capture every feature that’s in CarPlay, and hopefully, customers are seeing that. I think it often gets more noise than it deserves.

The other thing beyond mapping that’s coming is better integration with texting. We know that needs to come, and it’s something that teams are actively working on. I mean, again, we have a great relationship with Apple.

I think the absolute world of their products. If I put myself in Apple’s shoes, imagine Apple was developing a Mac, and there was someone that had a software application — let’s maybe call it Windows — and they said, “We have a turnkey platform that everybody knows how to use,” would they have put that in their car? Would they have developed their own iOS? We know how that played out. So, as much as I love their products, there’s a reason that ironically is very consistent with Apple ethos for us to want to control the ecosystem.

Yeah, we’re going to make that a setting. I love that. It’s a good idea.

I’ll have to give you credit in the release notes. I’ll commit to it right here. Easy.

Oh, in the back? That’s a great question. Just [for] anybody who’s listening, we have an electronic release on the inside of the car instead of a manual latch, and the benefit of that is it allows the release to be software-defined, and you can open the door without necessarily having to pull a cable. In the back of the vehicle, there’s only electronic release.

So the scenario in which you need to get out of the vehicle in case of, let’s say, the vehicle going into water, what we’re actually working on is if the vehicle senses being submerged, the windows lower. That’s actually the most effective way to get out of the car, is to be able to climb out the window. So, that’s something we’re looking at very closely.

What we do on R2, whether there’s a handle or whether we lower the windows or use the front door, that’s a question. We haven’t answered that, but it’s one that a lot of people asked about. Well, it’s a very, very extreme corner case of a car being submerged, and there’s lots of ways to solve getting out of it that are beyond just the release.

What happens if I find myself in a lake? How do I get out? The reality is it’s very hard to open a door once you’re submerged, as you probably know, so the better thing to do is to have the windows open as it’s sinking. We could. Yeah, we could.

We could definitely do that. I’m just trying to think of..

. It’s never..

. The last one, the mirror tilting I agreed with. This one doesn’t bother me, but now that you brought it up, now I’m sure I’ll see something, but yeah.

This will be the first call I make after, to the team, to see if we can fix that. The “Nilay Anti-Zoom” we’ll call it. Oh, I wish tomorrow.

I’m so excited about the R3X. It’s probably the car that we get the most questions about, and I mean the packaging on it is just exceptional. As soon as we possibly can, but we’re not giving a date.

We are learning from previous mistakes we made, which is when we launched R1, we launched R1T, R1S, and the commercial van all at the same time, and we sort of almost choked to death trying to ingest that much complexity. So, what we’re doing with this new platform is we’re launching R2 first, allowing some time to get that stable, and then launching R3. I will say this: The first R3 that we’re launching, it’s going to start with R3X, and then we’ll bring in base R3 after R3X.

Yeah, that’s news. We haven’t announced exactly when. But everyone at Rivian is highly incentivized because we all want so bad and to get the R3X in as soon as possible.

Yeah, this was fun. Thanks so much..