(Excerpted from Simply Nahil: a maverick with the Midas touch , the Nahil Wijesuriya autobiography) While operating the tugs ‘MT Sigiri’ and ‘MT Nilgiri’ through Off Shore Marine Services – an East West subsidiary – a Single Point Mooring Buoy or SPMB was installed off shore from the Colombo Port. An SPMB consists of a buoy that is permanently moored to the seabed by. utilizing multiple mooring lines/anchors/chains allowing cargoes of liquid petroleum products to be transferred from tankers out at sea.

An SPM contains a bearing system that allows a part of it to rotate around the moored geostatic subsea manifold connections and weathervaning tankers. SPMs are capable of handling ships of any tonnage, including the very large crude oil carriers when no alternative facility is available. In shallow water, SPMs are used to load and unload crude oil and refined products from onshore and offshore oilfields or refineries, usually through some kind of storage facility.

These buoys are usually suitable for use by all types of oil tankers. and the moorings usually supply to dedicated tankers which can moor without assistance. Whenever a tanker brings crude oil into Colombo, she is anchored off the edge of the port and a flexible hose goes down connecting to one of the stationary pipes on the pier.

In order to secure the ship from drifting or the connected hose being damaged during bad weather, a tug is in attendance to keep the ship in place. Ever since the SPBM was installed by the Hong Kong-based Swire Group – owners of Cathay Pacific Airways, a tug on a renewable charter was also provided by them. This was a lucrative business that was hijacked by the Swire Group, thereby every tender forwarded by the Petroleum Corporation carried the exact specifications of the Swire Group’s tug on charter, thus stalling everyone else from getting the business.

This tug was painted red. When Nahil realized that local service providers were being sidelined by the contractor, with their focus on the Swire Group tug, he advised those from Petroleum Corp involved in this project, since they were so specific, to include the Swire Group name by painting it on the back of the tug. Off Shore Marine Services (an East West subsidiary) owned two tugs that did not meet with the standards or specifications required, although the specifications could be rectified by modification.

There is something known as a ‘bow thruster’ which is fixed on the vessel underwater — a little tunnel with a pipeline inside that pushes the water to either side as a way to get control of the ship. Off Shore Marine Services had a 150 horsepower tug. However the requirement of the contractor, Petroleum Corporation and the Ports Authority, was 200 horsepower.

Since its bow was under capacity, Off Shore Marine Services gave a guarantee to the contractor indicating it would upgrade the bow thruster to the required capacity. Lester was in Germany buying the 200 horse power bow thruster when the Iran/Iraq war broke out. Unfortunately, due to this unpredicted incident, he couldn’t ship it immediately because of a new ruling requiring a 48-hour cooling period for all cargo, in case they were explosives.

With a confirmed deadline set for installation and handing over, the only viable solution was to ship it as personal baggage, which Lester did, using his credit card. Thankfully the 48-hour rule did not apply to his 1.5 tonnes of personal baggage! Nahil modified a Massey Ferguson tractor and mounted it on the tug, so the wheel could pull the rope.

They won the contract for two years. Nahil says of the Ports Authority people, “They were always appreciative of real effort like this and supported us 100%.” It was now the early 1980s.

While his business boomed. his personal life was in shambles. The late nights and almost every week spent building his empire was taking a toll on his marriage.

Although a great provider, he was ‘never home,’ according to Indrani. She was right. No amount of excuses could get him out of this situation.

He emphases that the concept of ‘happy wife, happy life’ was never for him. Maybe the fact that he is a stickler for detail contributes to his inability to find any person, man or woman, who meets his exceptional standards long- term. He tells me that he is a “hands-on person and a perfectionist”.

In his youth he figured out that delegating never works for him, making him seem obnoxious. “Who cares? Isn’t getting the job done of utmost importance? I am a 100% results-oriented person. In my pyramid of life at the acme comes work, with everything else trailing behind in whatever order.

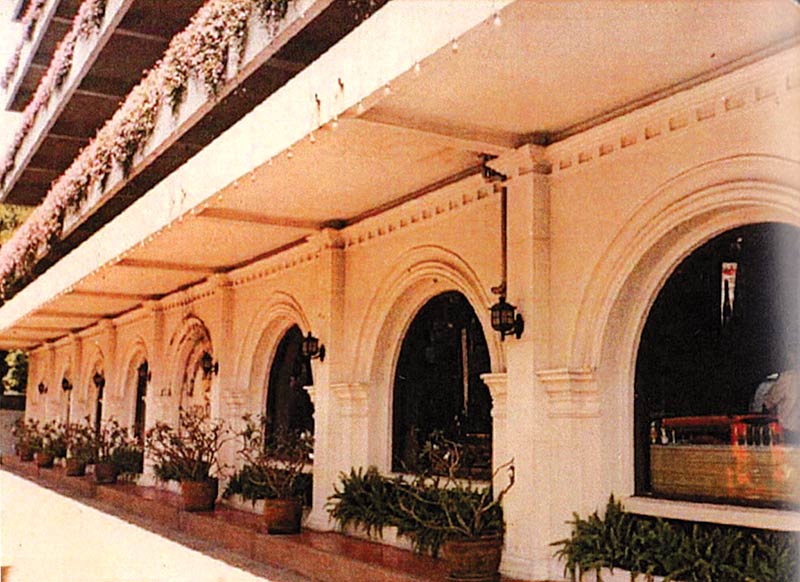

” Beautiful Arches at the Chiang Mai Hotel Nahil was in Singapore in the Cross World Navigation office of Captain Charles Gnanakone, on the 20th floor off Robing House, when Lester called him saying, “Nahil, I have something terrible to tell you.” Nahil says. “My first thought was someone had died.

” Lester said ‘Indrani has left you’. In absolute relief, I said, ‘Is that all?” Nahil was relieved because he was expecting to hear about a death in the family or some other disaster. Lester added: “Anyway, don’t do anything rash,” to which he replied, “I’m with Charlie now, the window is open, and I am about to jump off.

” His little joke cut through the seriousness of the conversation and they laughed it off. Nahil got back to Colombo once his work was done to find out that Vajira, who was around 18 months at the time, had been taken to Nuwara Eliya by Indrani in an ‘Eveready’ van and was living there in a guest house. Nahil borrowed Lester’s car, and hastened to Nuwara Eliya accompanied by Maggie, baby Vajira’s nanny, with details of their whereabouts, first dropping in to see his father in Kandy to keep him informed, After which he proceeded to Nuwara Eliya.

Once he got there he did a stakeout for the ‘Eveready’ van and found it parked opposite the Priory Guest House on High Street. He went in, picked up his son and headed straight to the Police station, where he gave them a statement to the effect and brought Vajira back to Colombo. After this he left their marital home and took refuge at No.

36, Siripa Road, the home of his late friend, Ana Malalgoda who was a close buddy. A few days later he was advised by his sisters that he should let his wife have custody of the boy for various reasons, one being his tender age, which he says “made sense” at the time,, He therefore gave Indrani full legal and physical custody of Vajira. By April of that year, Indrani and Nahil separated, with Indrani and Vajira living in her recently-acquired house in Dehiwala.

Finally, they divorced in 1982 and she remarried. Later on, after the brouhaha had settled, he moved to an annex, a garage extension down Havelock Road, owned by Rienzie Perera. Initially, Nahil had access to Vajira whenever he wanted to visit him.

However, subsequently his visits were restricted and he could see Vajira only at Indrani’s home. Even taking Vajira to the beach was not a possibility. Ana had a heart issue and needed funds to go in for a heart bypass.

In order to raise money for the operation, he wanted to know if Nahil would be interested in buying a block of land behind the Grand Hotel he owned in Nuwara Eliya “I was enthusiastic. Besides helping Ana, the location of the land seemed great. I said to Ana ‘let’s go take a look at it.

’ Once they got there, sitting inside the car, he requested Ana to point out the boundaries of his property. Ana just waved his hands around and said, “Somewhere there, machang.” Noting the potential, he agreed to buy the land.

After settling Ana he developed the land, paved a new road right up the hill bordering one side of the land, opened the by-pass, blocked the land out and sold it all off within weeks of developing the site. Driving pass the land recently, he says, “It’s heartening to see some nice hotels built on this site after the road was paved. Interesting stuff.

” He then fondly recalls a trip he made to Chiang Mai, Thailand with Ana, Nawaz Rajabdeen, and customs lawyer M.L.M.

Ameen, where they stayed at a hotel with beautiful arches. Back on the subject of his business, it was by now a fully-fledged company with an excellent infrastructure in place geared to handle all aspects of shipping and road haulage. It was well-equipped and had the necessary haulage equipment to transport containers and heavy machinery throughout the island.

The heavy vehicles and equipment were parked at their container yard, down Dutugemunu Mawatha, Peliyagoda. It was during this era that under the accelerated Mahaweli development programme the Victoria Dam project which was originally proposed in 1961, was sped up by the newly-elected J.R.

Jayewardene Government in 1977 on a plan prepared with the assistance of the United Nations Development Programme (UNDP) and the Food and Agriculture Organization (FAO) after a study of the project. The purpose of the proposed project was to ease economic difficulties within the country. It was under the purview of the UNP Government’s Minister of Mahaweli Development, Mr.

Gamini Dissanayake. The plan was implemented to irrigate 365,000ha of land and provide 470 MW of electricity. The construction of the project was inaugurated in 1978, with the implementation of the main structure in 1980 and completed in 1985.

The construction of the dam tunnel was a joint venture between two British firms, Balfour Beatty and Edmund Nuttall, while the Constain group, a British technology based construction and engineering company carried out the construction of the power stations. After the project was sanctioned there was a fleet of local haulage companies, including East West Haulage, Cargo Boat Dispatch Co., Renuka Transport and D.

P. Jayasinghe — to name a few — with their sights set on clinching the transport for this project including similar projects being developed simultaneously. During this era, there were no 40-foot trailers available for road transport, with the only available trailer working inside the port maintained by Colombo Dockyard.

The Kotmale project was being handled by a Swedish firm, Skanska. It must be pointed out and highlighted that Mr. Gamini Dissanayake maintained a very professional approach to awarding the transport contracts.

There was no way he could be influenced or pressured into channelling any of the contracts to family or friends in the business. The contracts were awarded strictly based on how well equipped and experienced the contractor was. East West Haulage was very well equipped, owning a fleet of sophisticated haulage equipment they had invested in, thus enabling it to clinch a good part of the Victoria Dam haulage, which eventually extended to Kotmale, Randenigala, Madhuru Oya and Kelanitissa.

These were purpose-built haulers designed by East West. It was obvious to all that East West Haulage was transporting really large and difficult cargo to the dam sites, while the other contractors were hauling stuff like cement bags and steel reinforcement beams, among a host of other simple cargo. “It seemed that all the complicated cargo was directed for haulage only by us,” says Nahil.

Among the ‘melting pot’ of foreign nationals involved in these projects was a German, Mr. Koslowski, a freight forwarder, representing the German shipper to whom East West Haulage was a subcontractor, responsible for hauling its freight from the Colombo Port to the dam site. Working directly for the German freight forwarder and not the locally-based contractor was an important advantage.

Usually before a large piece of machinery was transported, the size of it in a box – length, breadth, height and a ‘3D’ image, pointing to the centre of gravity is sent with the pre-shipment details, for the hauler to plan out the transport accordingly. On receiving the specifications of a particularly large package, to which a quotation was forwarded according to the specifications received by East West, including the transport cost based on transporting the package along the shortest route to Kotmale, which was via Gampola. To their dismay the package, once it arrived posed a problem as it was a Swedish Koni Gantry crane which was a foot wider than the Gampola steel bridge.

The hindrance was the catwalk on the gantry. Sourcing further route options they found the road via Wellawaya to be the next best option, though it was a major circuitous and dangerous route. A quote was forwarded to the shipper based accordingly, which ran into a colossal amount of money.

The gantry crane is built like a trolley that moves vertically and functions as a lift for the turbines of the powerhouse during maintenance. Nahil suggested to Mr. Koslowski that they should cut off the catwalk on the crane, enabling it to be hauled on the original route via Gampola.

Immediately Kos wanted the price quoted to be reduced but Nahil insisted the price remains the same but if it made him happy, they could haul it along the circuitous route. Then Kos insisted the price should be reduced since they were going to cut off the catwalk of the crane. Nahil refused to reduce the price, requesting a letter from Kos to the effect that, if anything should happen to the equipment in transit since he insisted they take the circuitous route, even though a workable solution had been found, he would be responsible.

Kos caved in and acceded to plan B, requesting that they weld the catwalk back by X-ray super first class welding. Nahil agreed to the request saying, “No worries!” He made a huge profit considering the welder signed up to do the job was a former welder from Colombo Dockyard, who did it at no charge. It seemed that Mr.

Koslowski a.k.a.

Kos was a mini legend at EW. He had nothing to do with his time, thus wasting Nahil’s time as well by being a regular visitor to the East West office, while they were operating from the Cargills building in Fort. Whenever Nahil came up with a good idea, he’d say ‘Hey Nahil that’s a great idea,’and then he would return a couple of days later trying to sell Nahil’s idea back to him until Nahil would gently remind him that it was his idea to begin with.

Subsequently, ‘doing a Koslowski’ was a term used at East West on anyone trying the same lark. As the Victoria project was coming to a close, they bought a 56-wheel trailer from Costain. This trailer was used to transport the penstock, a structure of big steel tubes that take the water down.

This is the biggest trailer available on the island. The trailer is an all-wheel steer and the bed can be lifted about two feet off the ground. This trailer was used by East West Haulage for the Kelanitissa turbines since there were no cranes at the time capable of lifting these machines.

The heavy load is put down by the ship which has the gear to load it on to this trailer, after which they would drive over the foundation, put bars across and lower the trailer. Once the turbines are placed on the steel bars, the trailer moves off. The turbine is lowered into the foundation using pneumatic jacks.

Nahil found this extremely thrilling. He loved handling these operations personally, never letting anyone steal his joy. In retrospect, he says, “this was really simple stuff.

”.